Frequently asked questions

Company News

- Aluminum veneer: not just a material, it is a fashionable choice for construction!

- Aluminum curtain wall: the beauty of architecture, the soul of technology

- New trend of aluminum veneer: the beauty of light luxury, the new favorite of home furnishings

- Aluminum curtain wall: the fashionable new darling of urban architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new proposition for personalized space

- What are the design styles of punched aluminum veneer?

- Aluminum Charm, Coolness Protection - Unveiled Aluminum Alloy Air Conditioner Cover

- Aluminum alloy air conditioning cover, a new choice for cool summer!

- Customized personality, new trend of aluminum veneer

Frequently asked questions

- What is the production cost of aluminum veneer? What is the price?

- What are the unique design and application advantages of aluminum veneer curtain walls?

- What are the unique advantages and characteristics of aluminum veneer?

- What is the current supply and demand situation in the aluminum veneer market?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of aluminum veneer?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 17, 2025 10:19:58

- Click:0

What is the production process of aluminum veneer?

Abstract: This article will elaborate on the production process of aluminum veneer from four aspects, including raw material preparation, sheet processing, surface treatment, and finished product production.

1、 Raw material preparation

1. Material selection: The main raw material for aluminum veneer is high-purity aluminum alloy sheet, such as aluminum alloys 3003 and 5005. These aluminum alloys have excellent weather resistance, corrosion resistance, and mechanical strength, making them suitable for outdoor building decoration.

2. Cutting: Raw materials are cut according to the design dimensions, usually using CNC cutting machines and shearing machines for precise cutting to ensure the accuracy of sheet size.

3. Bending: The cut aluminum plate is bent using a hydraulic bending machine to form the desired shape and angle, while ensuring the flatness and stability of the plate.

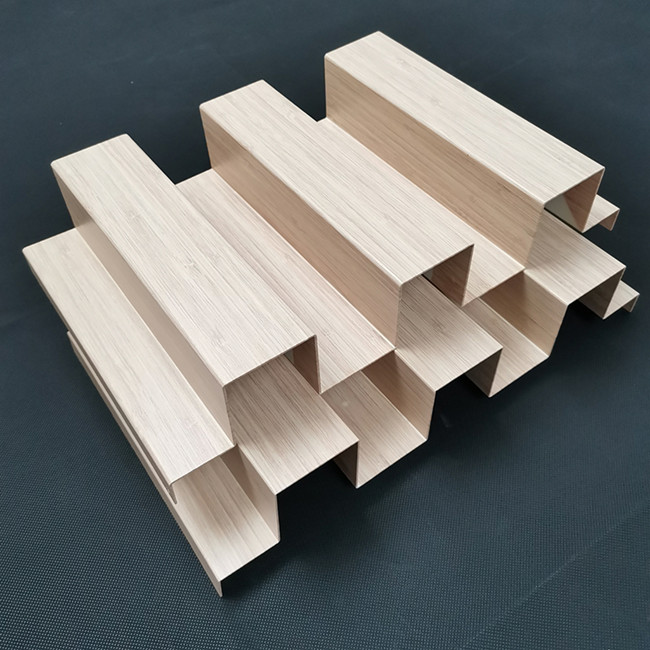

2、 Sheet metal processing

1. Mold making: According to the design drawings, make molds suitable for aluminum veneer. The design of the mold should take into account the process requirements such as bending, cutting, and connecting of the sheet metal.

2. Cutting and processing: Use a CNC cutting machine to cut aluminum plates according to the required size, and can also perform special shapes such as drilling and hollowing.

3. Forming processing: Using equipment such as molds and hydraulic presses, aluminum plates are stamped or bent into the desired shape, such as flat plates, convex surfaces, concave surfaces, etc.

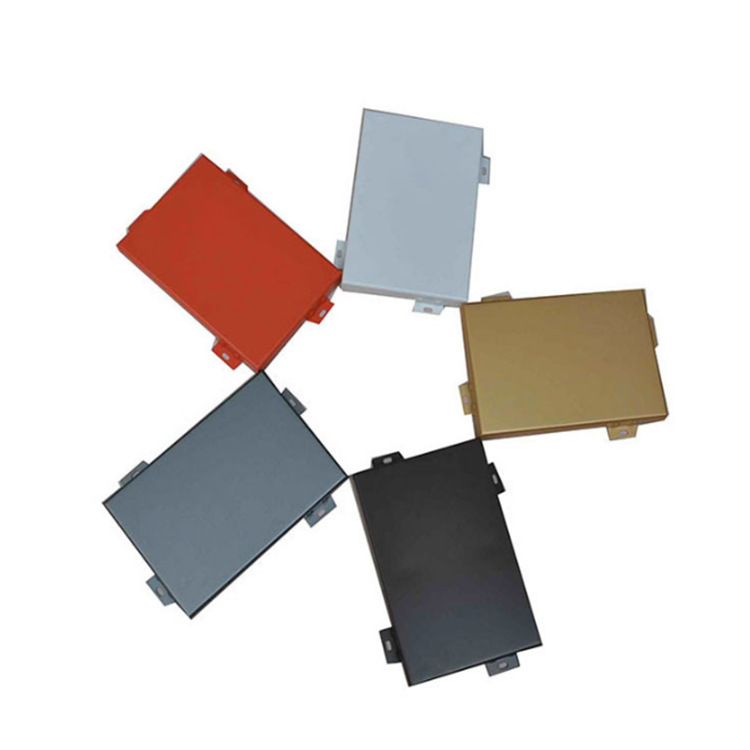

3、 Surface treatment

1. Oxidation removal treatment: Use acid or alkali washing methods to remove the oxide layer on the surface of the aluminum plate, achieving a clean and bright effect on the surface.

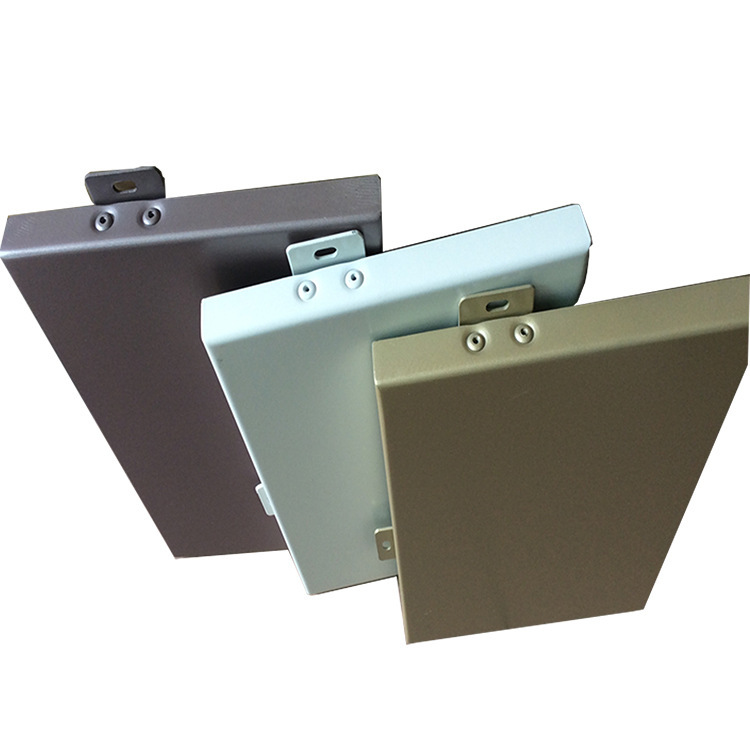

2. Spray coating treatment: Using processes such as electrostatic spraying, baking paint, or powder spraying, the surface of aluminum veneer is coated with colored or protective paint to increase its aesthetic appeal and durability.

3. Texture processing: According to design requirements, aluminum veneers are processed using embossing or texturing machines to create various texture effects and increase decorative value.

4、 Finished product production

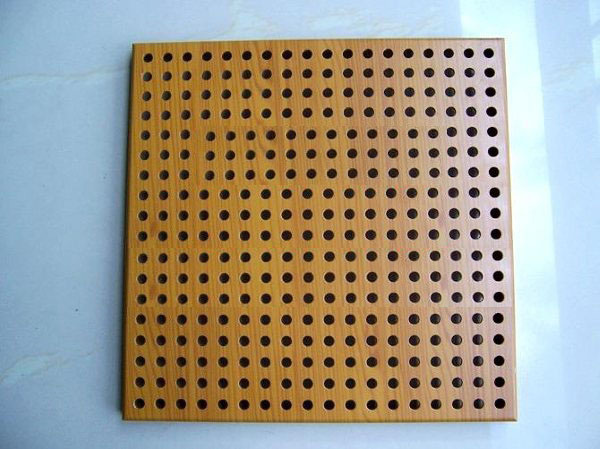

1. Punching connection: Punching holes in aluminum veneer for installation and fixation on building structures, usually using rivets, screws, or suspension systems for connection.

2. Cutting and shaping: Cut and shape the aluminum veneer according to actual needs for installation and splicing, while ensuring the flatness and beauty of the edges.

3. Quality inspection packaging: Conduct quality checks on finished products to ensure they meet technical standards and design requirements. Then proceed with packaging and take appropriate protective measures to prevent damage during transportation and installation.

5、 Summary

The production process of aluminum veneer involves four aspects: raw material preparation, sheet processing, surface treatment, and finished product production. Through a good production process and strict quality control, aluminum veneer can meet the needs of architectural decoration, while also having advantages such as weather resistance, corrosion resistance, and decorative properties, and is widely used in modern architectural design.

- Previous Page: None

- Next page:What are the different types of aluminum veneer production processes and their respective characteristics?

Customer service QQ

Customer service QQ