Frequently asked questions

Company News

- Aluminum alloy air conditioning cover: cool in summer, a new choice for home fashion!

- Aluminum curtain wall: the fashionable coat of modern architecture

- The fashion comeback of aluminum veneer: not just decoration, but attitude!

- Aluminum alloy air conditioning cover: the fashionable guardian of home style

- Aluminum alloy air conditioning cover: the cool guardian of summer homes

Industry dynamics

- The importance of aluminum veneer in architectural decoration

- Aluminum veneer, the "silver guardian" of modern architecture

- Aluminum veneer customization, creating a new proposition for personalized space

- Aluminum Curtain Wall: The Perfect Integration of Architectural Aesthetics and Technology

- Material and quality assurance of painted punched aluminum veneer

Frequently asked questions

- What are the different types of aluminum veneer production processes and their respective characteristics?

- What are the unique design and application advantages of aluminum veneer curtain walls?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

- What is the production cost of aluminum veneer? What is the price?

- What is the current supply and demand situation in the aluminum veneer market?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production cost of aluminum veneer? What is the price?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- 发布时间:2025-03-18 06:13:12

- Click:0

What is the production cost of aluminum veneer? What is the price?

Abstract: This article will elaborate on the production cost and price of aluminum veneer from four aspects, including raw material cost, manufacturing process cost, human resource cost, and market competition factors. By analyzing these aspects, we can gain a more comprehensive understanding of the production cost and price formation mechanism of aluminum veneer.

1、 Raw material cost

1. Aluminum price: The main raw material for aluminum veneer is aluminum, and its price directly affects the production cost of aluminum veneer. At present, the price of aluminum is determined by market supply and demand. With the tight supply of aluminum resources and the increase in costs, the price of aluminum is also showing an upward trend.

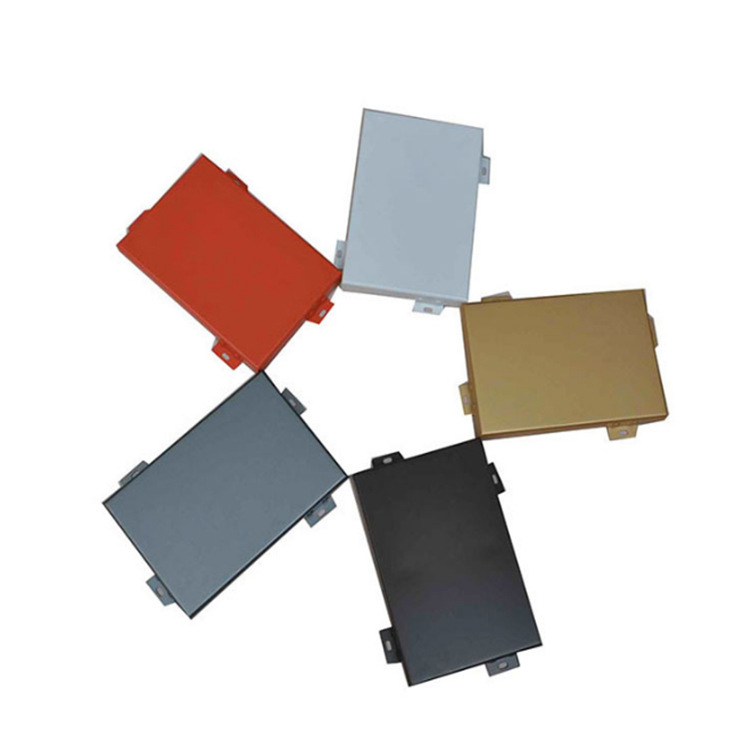

2. Coating material price: Aluminum veneers usually require coating treatment to improve corrosion resistance and decorative effects, and the price of coating materials is also an important factor affecting the production cost of aluminum veneers. At present, the competition in the coating material market is fierce, and there are certain differences in the prices of coating materials of different brands and qualities.

3. Other auxiliary materials: In addition to aluminum and coating materials, the production of aluminum veneer also requires some auxiliary materials, such as glue, screws, etc. These auxiliary materials have relatively low prices, but they also need to be taken into account in production costs.

2、 Manufacturing process cost

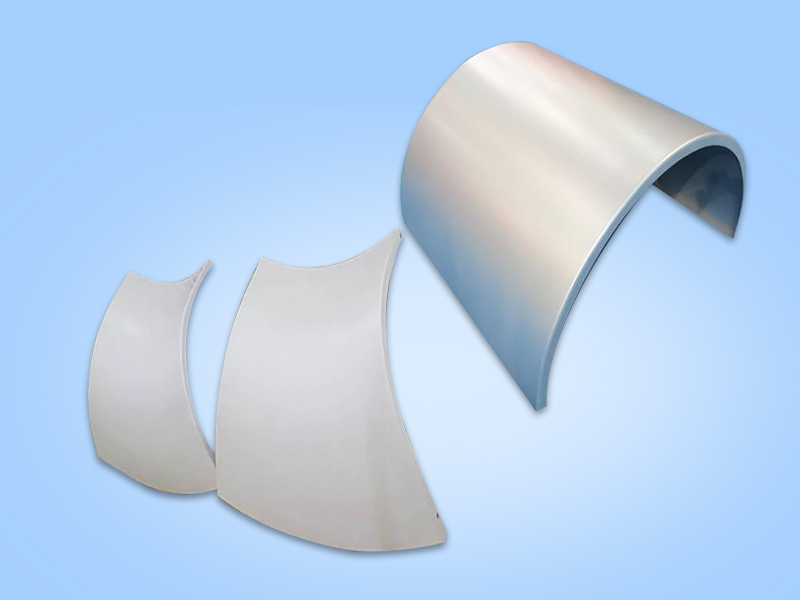

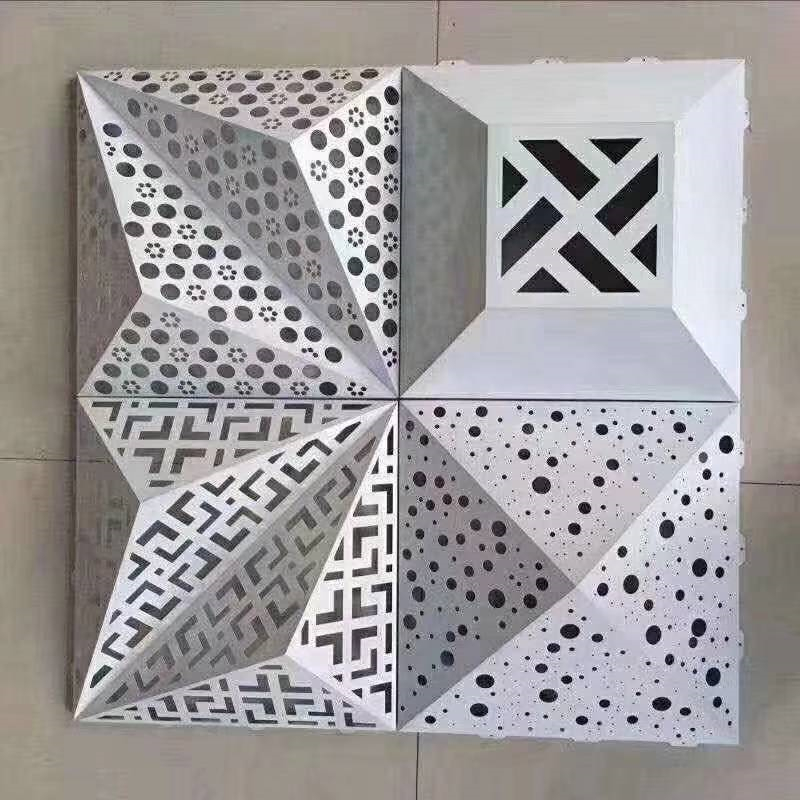

1. Processing cost: The production process of aluminum veneer includes cutting, bending, punching and other processing steps, which will generate certain labor and mechanical costs. The level of processing costs mainly depends on the production scale, equipment technology level, and worker skill level.

2. Equipment depreciation and maintenance costs: The purchase, depreciation, and maintenance of aluminum veneer production line equipment are also part of the manufacturing process costs. The investment and use of equipment are directly related to production efficiency and product quality, therefore, good equipment management is the key to reducing manufacturing process costs.

3. Energy consumption cost: The production process of aluminum veneer requires a large amount of electricity and gas consumption. The level of energy consumption costs is related to energy market prices and energy utilization efficiency. Reasonable control of energy consumption costs can effectively reduce manufacturing process costs.

3、 Human resource costs

1. Employee salary: The production process of aluminum veneer requires a certain number of employees to participate, and employee salary is an important component of human resource costs. The level of employee wages is related to the regional economic level, industry competition, and employee skill requirements.

2. Training costs: In order to improve employee skills and production efficiency, companies usually conduct training. Training expenses are included in human resource costs and have a significant impact on improving production efficiency and product quality.

3. Management expenses: Human resource management requires a certain amount of investment, including recruitment costs, welfare benefits, and corporate culture construction. These management expenses are also a part of human resource costs.

4、 Market competition factors

1. Market demand: The production cost and price of aluminum veneer are greatly affected by market demand. When the market demand is strong, the production scale of aluminum veneer increases, and the cost may decrease; On the contrary, when market demand is insufficient, costs may increase.

2. Industry competition: The aluminum veneer market is fiercely competitive, and there are differences in production costs and prices among different enterprises. Large scale and technologically advanced enterprises usually have lower production costs, which can attract customers at more favorable prices.

3. Stability of raw material supply: The production of aluminum veneer requires a large amount of aluminum material supply, and the adequacy of raw material supply directly affects costs. When the supply of raw materials is unstable, the price of aluminum may rise, which in turn affects the production cost and price of aluminum veneer.

5、 Summary:

Based on the above analysis, it can be concluded that the production cost of aluminum veneer is influenced by multiple factors, including raw material costs, manufacturing process costs, human resource costs, and market competition factors. Meanwhile, the price of aluminum veneer will also fluctuate according to changes in these factors. Enterprises need to consider these factors comprehensively when producing aluminum veneer to ensure the control of production costs and the rationality of product prices. Only on the basis of reasonable production costs and prices can we provide high-quality aluminum veneer products and gain competitive advantages in the market.

Customer service QQ

Customer service QQ