Corporate News

Company News

- Aluminum veneer: the fashionable "coat" of architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum alloy air conditioning cover: the secret weapon to protect the coolness of home!

- Aluminum veneer customization, creating personalized spatial aesthetics

- Aluminum curtain wall: the beauty of architecture, the soul of technology

Industry dynamics

- Aluminum veneer: the "silver fashion" code for modern architecture

- Aluminum curtain wall: a shining pearl in modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Innovative aluminum veneer pricing strategy drives industry development

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- What is the production cost of aluminum veneer? What is the price?

- What will be the future innovation and development trend of aluminum veneer?

- What are the different types of aluminum veneer production processes and their respective characteristics?

- What is the current supply and demand situation in the aluminum veneer market?

- How to identify and select high-quality aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer: the "hidden master" of the construction industry

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- 发布时间:2025-03-20 08:52:49

- Click:0

Ladies and gentlemen, today we will talk about a "hidden master" in the construction industry - aluminum veneer. Does this name sound a bit unfamiliar? Don't worry, listen to me slowly.

Aluminum veneer, as the name suggests, is a single-layer sheet made of aluminum. It is lightweight, corrosion-resistant, easy to process, and widely used in fields such as construction, decoration, and transportation. Although it is not as dazzling as marble or glass, it silently adds bricks and tiles to our lives.

Let's talk about the "lightness" of aluminum veneer first. You know what? The density of aluminum is only 2.7 grams per cubic centimeter, much lighter than steel. This means that building structures made of aluminum veneer will reduce overall weight, thereby lowering construction costs. Just like the aluminum alloy doors and windows we usually use, which are both beautiful and practical, isn't it amazing?

Let's talk about the "corrosion resistance" of aluminum veneer. The surface of aluminum veneer is specially treated to form a dense oxide film, which effectively resists the erosion of corrosive substances such as acid and alkali, salt spray, etc. This makes aluminum veneer more durable and has a longer service life in outdoor environments. Think about it, those tall and magnificent buildings, with their shiny appearance, cannot be separated from the contribution of aluminum veneer.

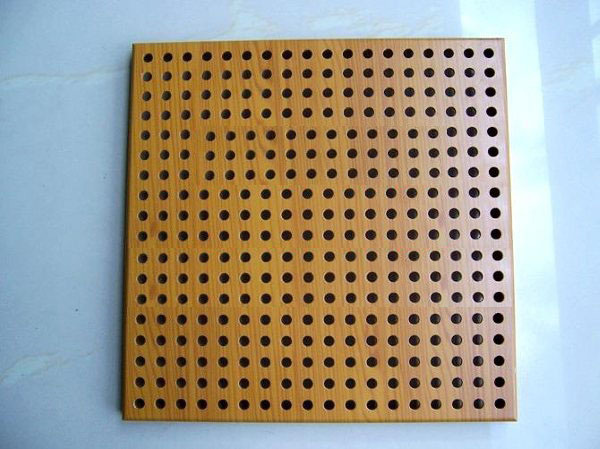

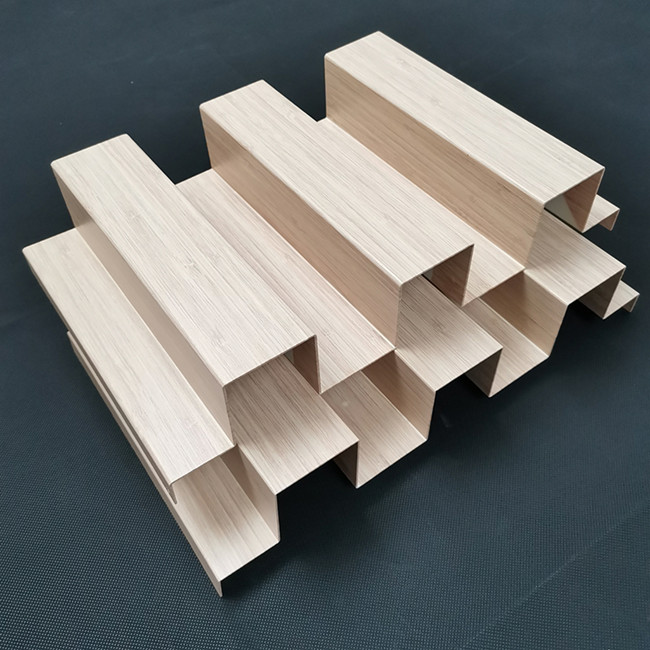

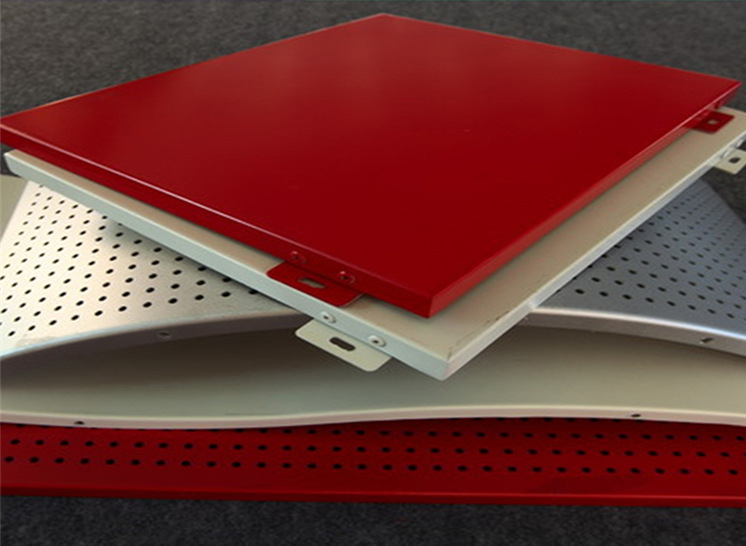

The most commendable aspect of aluminum veneer is its ease of processing. Aluminum veneer can be processed into various shapes, such as flat, curved, curved, etc., to meet the needs of various architectural styles. The surface of aluminum veneer can also be treated with spraying, baking paint, transfer printing and other processes, with diverse colors and rich textures, adding infinite charm to the building.

What are the applications of aluminum veneer in construction? Let me give you a few examples:

1. Exterior wall decoration: Aluminum veneer, as an exterior wall decoration material, has the advantages of beauty, durability, and easy maintenance. In recent years, more and more buildings have adopted aluminum veneer as the exterior wall material, making the appearance of buildings more fashionable and modern.

2. Stair handrail: Aluminum veneer can be processed into stair handrails, which are both beautiful and safe. Compared to traditional wrought iron handrails, aluminum veneers are lighter, easier to clean, and less prone to rusting.

3. Elevator doors: Aluminum veneer can be made into elevator doors, which not only ensures the safety of the elevator, but also enhances the overall level of the elevator.

4. Transportation: Aluminum veneer is also widely used in the field of transportation, such as subways, high-speed trains, ships, etc. Aluminum veneer can be made into components such as carriages and hulls, reducing vehicle weight and improving operational efficiency.

How is aluminum veneer transformed from a raw material into the building material we see in our daily lives? Next, I will take you into the production process of aluminum veneer.

Aluminum ingots are made into aluminum plates through processes such as melting, casting, and rolling. This process is like an alchemist refining an elixir, requiring a series of complex chemical reactions and physical changes.

Aluminum plates undergo surface treatment such as oxidation, spraying, baking paint, etc., forming a protective film to improve the corrosion resistance of aluminum veneers. This process is like putting a "protective suit" on the aluminum plate, allowing it to survive in harsh environments.

Aluminum sheets are processed through stamping, cutting, bending, and other techniques to produce various shapes of aluminum veneers. This process is like a magician performing magic, turning aluminum plates into various shapes.

Aluminum veneer is assembled, welded and other processes to produce aluminum veneer products required for construction. This process is like a construction worker building a house, installing aluminum panels into various parts of the building.

Aluminum veneer plays a crucial role in the construction industry. It not only provides us with beautiful and durable building materials, but also contributes to the vigorous development of China's construction industry. Perhaps one day in the future, aluminum veneer will become a "hidden master" in the construction industry, leading the trend of architecture.

Aluminum veneer also has its limitations. Its strength and stiffness are relatively low, making it unsuitable for structures that can withstand large loads. With the development of technology, it is believed that aluminum veneer will have a wider range of applications in the future.

What I want to say is that although aluminum veneer is unknown, it has brought countless conveniences to our lives. Let's give a thumbs up to this' hidden master 'together!

Customer service QQ

Customer service QQ