Industry information

Company News

- Aluminum veneer: a fashionable interpretation of industrial aesthetics

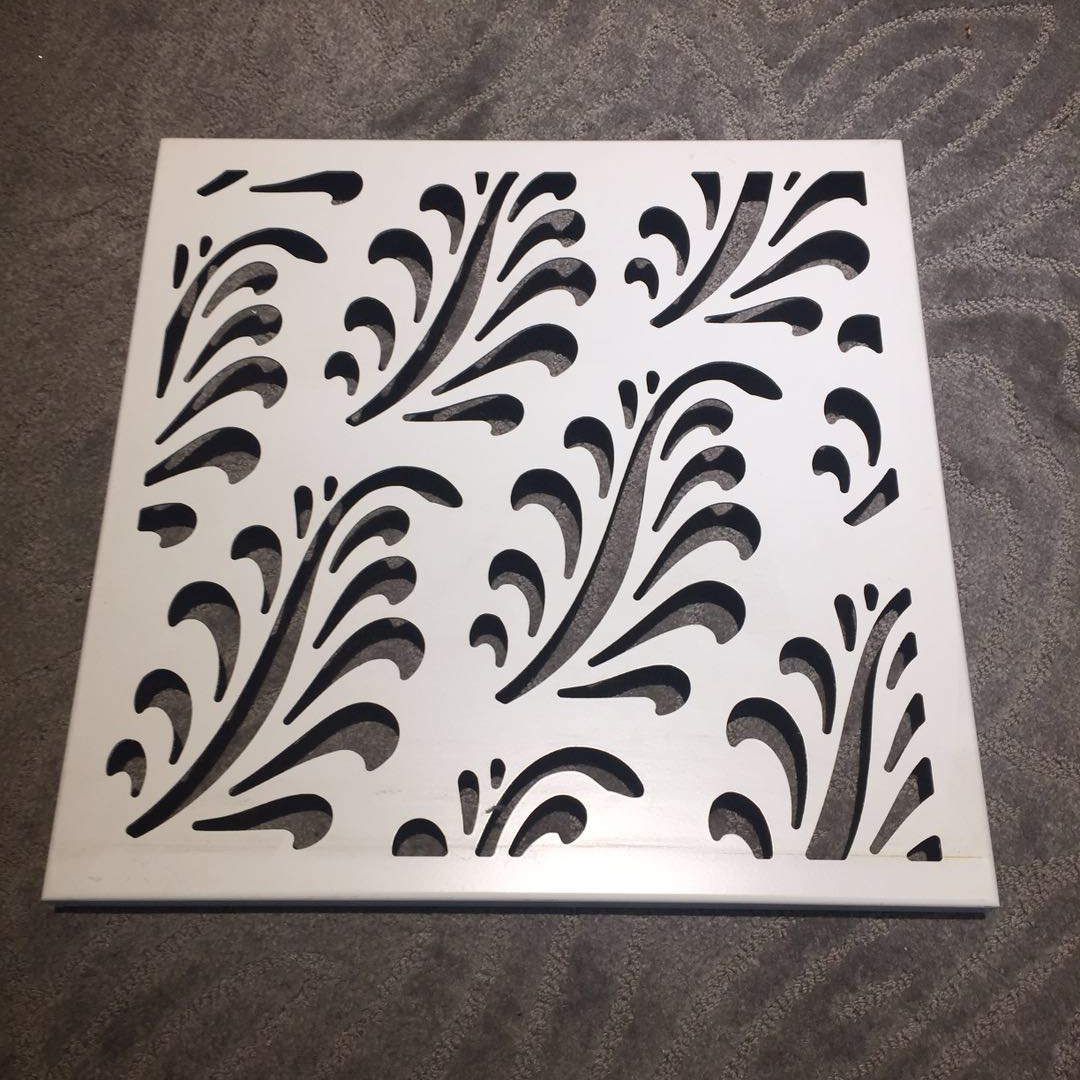

- Aluminum veneer customization, creating a new trend of personalized space

- Customized aluminum veneer, make your home look brand new!

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer: a low-key and fashionable star in modern architecture

- Aluminum air conditioning cover, a great helper for cool summer!

- Aluminum alloy air conditioning cover, the cool guardian of summer home!

- Aluminum curtain wall, the "mysterious veil" of modern architecture

- Aluminum veneer: the beauty of architecture, the choice of light luxury

Frequently asked questions

- What is the current supply and demand situation in the aluminum veneer market?

- What are the common styles and characteristics of the application of aluminum veneer in the home decoration industry?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

- What is the production cost of aluminum veneer? What is the price?

- How to identify and select high-quality aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Types and characteristics of aluminum veneer coatings

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- 发布时间:2025-03-16 09:52:02

- Click:0

Types and characteristics of aluminum veneer coatings

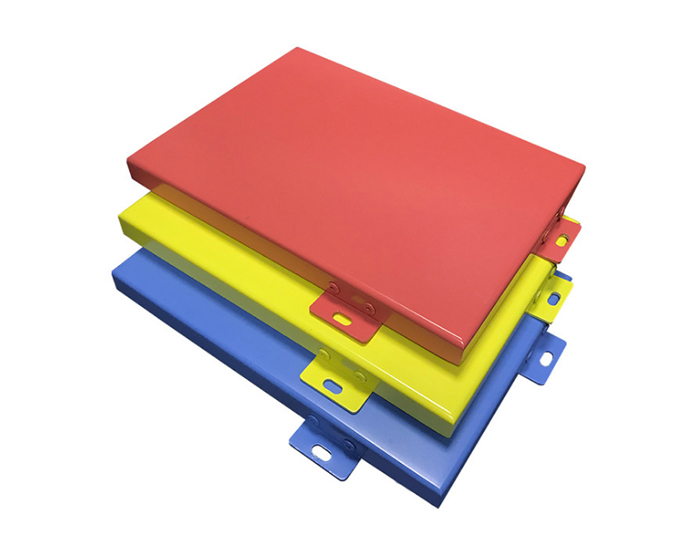

Aluminum veneer is a common building decoration material with advantages such as lightweight, weather resistance, and fire resistance. The coating of aluminum veneer is an important component for protecting and beautifying the aluminum veneer. This article will elaborate on the types and characteristics of aluminum veneer coatings from the following four aspects.

1、 Polyester coating

Polyester coating is one of the most common coatings on aluminum veneer. This coating uses polyester resin as the base material and is made using a thermosetting process. Polyester coating has good weather resistance and can resist the erosion of ultraviolet rays, oxidation, and corrosion. In addition, polyester coating also has excellent adhesion and wear resistance, which can maintain the bright color and smooth surface of aluminum veneer for a long time.

However, the thermal stability of polyester coatings is relatively poor and may undergo discoloration or deformation in high-temperature environments. Therefore, when selecting polyester coatings, it is necessary to evaluate and choose based on the specific usage environment.

2、 Fluorocarbon coating

Fluorocarbon coating is a type of advanced coating, commonly used in fluorocarbon polyester coating and fluorocarbon acrylate coating. This coating has excellent weather resistance and corrosion resistance, and can maintain color stability and surface smoothness for a long time. At the same time, fluorocarbon coating also has excellent self-cleaning function, which can resist the adhesion of pollutants, keeping aluminum veneer clean and novel in appearance.

However, the cost of fluorocarbon coating is relatively high and the construction difficulty is also relatively high. Therefore, fluorocarbon coatings are mainly used in buildings with high appearance requirements, such as high-end residential buildings, commercial squares, etc.

3、 Aluminum oxide coating

Aluminum oxide coating is a special type of coating that is formed by mixing aluminum oxide micro powder with an appropriate amount of resin and spraying it onto the surface of aluminum veneer. Aluminum oxide coating has good weather resistance and corrosion resistance, and is not easily corroded by ultraviolet rays, acid rain, and salt spray. In addition, aluminum oxide coating also has good thermal insulation performance, which can effectively reduce the energy consumption of buildings.

However, there are relatively few color options for aluminum oxide coatings, generally dominated by metallic colors. Therefore, when designing the appearance of aluminum veneer, it is necessary to match it according to the overall style and requirements of the building.

4、 Nano coating

Nano coating is a new type of coating technology that has emerged in recent years. By utilizing the special properties of nanomaterials, nano coatings can form a uniform protective film on the surface of aluminum veneer, with good weather resistance, acid and alkali resistance, and self-cleaning function. Nano coatings can also absorb and disperse ultraviolet radiation, improve the reflection effect of aluminum veneer, reduce heat absorption, and thus reduce the energy consumption of buildings.

However, the technology of nano coating is still constantly developing, with high costs and relatively complex construction requirements. Therefore, further research and improvement are still needed for the practical application of nano coatings.

Summary:

Aluminum veneer coatings can be divided into polyester coatings, fluorocarbon coatings, aluminum oxide coatings, and nano coatings according to different materials and processes. Each coating has unique characteristics and advantages and disadvantages, and the suitable coating should be selected according to the needs and environment of the building. In the future, with the continuous advancement of technology, the types and characteristics of aluminum veneer coatings will also continue to expand and improve to meet people's higher requirements for building appearance and functionality.

Customer service QQ

Customer service QQ