Industry information

Company News

- Aluminum alloy air conditioning cover, the guardian of summer coolness

- Aluminum alloy air conditioning cover: the fashionable guardian of summer home decor

- The modern aesthetic journey behind aluminum veneer

- Aluminum veneer: the fashionable "coat" of modern architecture

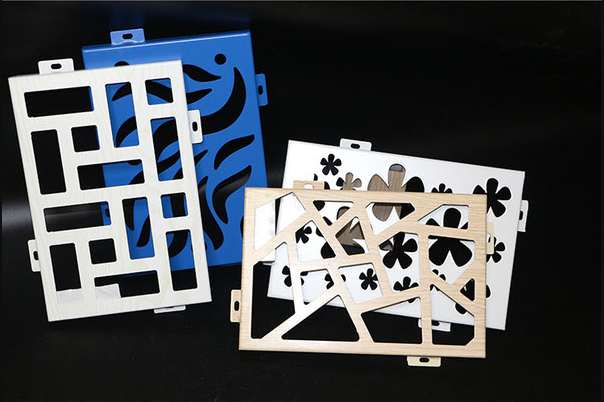

- Aluminum veneer customization, creating personalized space and new fashion

Industry dynamics

- Aluminum alloy air conditioning cover, the guardian of a cool summer!

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer, the beauty of the "hermit" in the construction industry

- Aluminum veneer: the new darling of the construction industry, an aesthetic revolution in details

- Aluminum alloy air conditioning cover: the secret weapon for cool summer!

Frequently asked questions

- What are the unique advantages and characteristics of aluminum veneer?

- What will be the future innovation and development trend of aluminum veneer?

- What is the current supply and demand situation in the aluminum veneer market?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

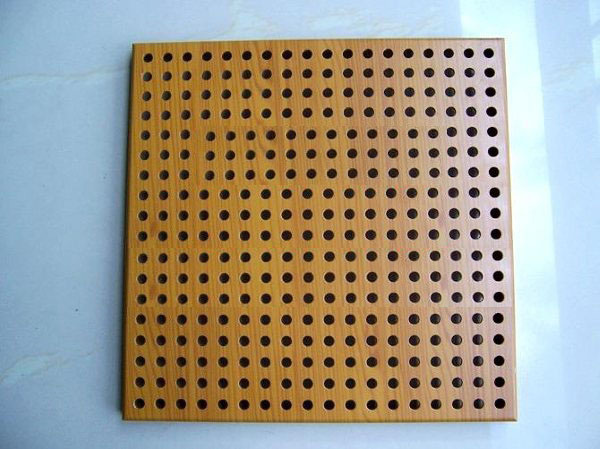

- What are the different types of aluminum veneer production processes and their respective characteristics?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to reduce the production cost of aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- 发布时间:2025-03-18 11:45:34

- Click:0

Abstract: In order to reduce the production cost of aluminum veneer, we can start from the following four aspects: material selection and procurement, production process optimization, equipment update and improvement, and human resource management. By controlling and adjusting these aspects, production efficiency can be effectively improved, costs can be reduced, and the competitiveness of enterprises can be enhanced.

1、 Material selection and procurement

1. Reasonable selection of raw materials: In the production process of aluminum veneer, reasonable selection of raw materials is the key to reducing production costs. Discovering high-quality, low-cost raw material suppliers that meet product standards and establishing long-term partnerships with them can ensure stable supply of raw materials and obtain more competitive prices.

2. Optimizing inventory management: Reasonably managing material inventory to avoid material surplus or shortage can reduce inventory management costs and capital occupation costs. Adopting advanced warehouse management systems and refined material planning to achieve precise inventory control.

3. Innovative material usage: In the production process, material waste can be reduced by optimizing material usage. For example, reusing or recycling waste materials, optimizing material cutting and processing processes, and reducing scrap and scrap rates.

2、 Production process optimization

1. Process reengineering and optimization: By reengineering and optimizing the production process, production efficiency can be greatly improved and production costs can be reduced. Simplify or eliminate complex, repetitive, or ineffective links in the production process to achieve the goal of increasing production capacity and reducing resource consumption.

2. Standardized operation: Establish standardized operation standards, train employees to master standardized operation processes, improve production efficiency, and reduce the occurrence of human errors. By standardizing operations, not only can production costs be reduced, but the stability of product quality can also be improved.

3. Quality management and monitoring: Establish a sound quality management system and implement comprehensive quality monitoring. By promptly identifying and resolving quality issues, reducing the rate of defective products and rework, improving production efficiency and product qualification rate, and thereby reducing production costs.

3、 Equipment updates and improvements

1. Introducing advanced equipment: Adopting advanced production equipment and technology can improve production efficiency, reduce energy consumption and labor costs. By introducing automated and intelligent production equipment, manual operations can be reduced, and production accuracy and stability can be improved.

2. Equipment improvement and maintenance: Continuously improve and maintain existing equipment to ensure stable operation and efficient utilization. Regularly conduct equipment maintenance and upkeep, promptly replace severely worn parts to extend equipment lifespan and reduce failure rates.

3. Energy conservation and environmental protection: Emphasize the energy-saving and environmental performance of equipment, reduce resource consumption and waste emissions. In the process of updating and improving equipment, select equipment with higher energy efficiency indicators, and strengthen the management of waste disposal and resource recycling.

4、 Human Resource Management

1. Training and skill enhancement: Emphasis is placed on employee training and skill enhancement to improve their professional quality and production skills. Through training, employees can better understand production processes and operational norms, improve work efficiency, and reduce the occurrence of production errors and accidents.

2. Incentive and reward punishment mechanism: Establish a reasonable incentive and reward punishment mechanism to stimulate employees' enthusiasm and creativity. By providing employees with reasonable performance rewards and promotion opportunities, we aim to increase their attention to work quality and efficiency.

3. Teamwork and communication: Strengthen teamwork and communication between departments and employees, improve production coordination and efficiency. By establishing a good team collaboration atmosphere, promoting information sharing and problem-solving, and reducing errors and delays in the production process.

5、 Summary

By controlling and adjusting aspects such as material selection and procurement, production process optimization, equipment updates and improvements, and human resource management, we can effectively reduce the production cost of aluminum veneer. Reasonably selecting raw materials and optimizing processes, introducing advanced equipment and strengthening skills training, implementing scientific quality management and monitoring, as well as motivating employees and promoting teamwork, will help enterprises reduce costs, improve efficiency, and achieve better development in the fiercely competitive market.

Customer service QQ

Customer service QQ