Industry information

Company News

- Aluminum veneer customization, creating exclusive space aesthetics

- Aluminum alloy air conditioning cover: a perfect fusion of fashion and practicality

- Aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum Curtain Wall: The 'Invisible Hero' of Modern Architecture

- Regional differences and demand in the aluminum veneer market

Industry dynamics

- Comparative analysis and application suggestions of 3mm aluminum veneer and other materials

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum alloy air conditioning cover: guarding summer coolness, showcasing home taste

- Aluminum veneer: a low-key luxury choice in modern architecture

- The charm of aluminum veneer is not just about its appearance

Frequently asked questions

- What are the different types of aluminum veneer production processes and their respective characteristics?

- What is the production cost of aluminum veneer? What is the price?

- What will be the future innovation and development trend of aluminum veneer?

- What are the unique design and application advantages of aluminum veneer curtain walls?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to the manufacturing process of 2.5mm fluorocarbon aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 28, 2025 14:26:13

- Click:0

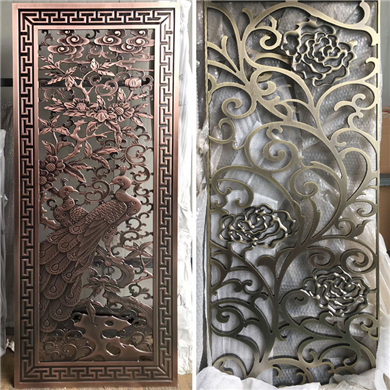

2.5mm fluorocarbon aluminum veneer is a high-end building decoration material, and its manufacturing process is crucial for ensuring its quality and aesthetics. Below is a detailed introduction to the manufacturing process of 2.5mm fluorocarbon aluminum veneer.

1、 Raw material preparation

The manufacturing of 2.5mm fluorocarbon aluminum veneer requires the use of various raw materials, including aluminum alloy sheets, fluorocarbon coatings, polyester films, etc. Before manufacturing, it is necessary to screen and inspect these raw materials to ensure their quality meets the requirements.

2、 Cutting and processing

Before manufacturing 2.5mm fluorocarbon aluminum veneer, it is necessary to cut it into the required size and shape. Generally speaking, CNC machine tools can be used for precision cutting to ensure cutting accuracy and dimensional accuracy. At the same time, it is necessary to polish and trim the cut edges to ensure their surface smoothness and aesthetics.

3、 Painting process

Coating is a very important step in the manufacturing process of 2.5mm fluorocarbon aluminum veneer. Firstly, the fluorocarbon coating needs to be mixed and stirred, and evenly sprayed onto the surface of the aluminum veneer using spraying equipment. During the spraying process, attention should be paid to controlling the thickness and uniformity of the coating to ensure that the quality of the fluorocarbon coating on the surface of the aluminum veneer meets the requirements. It is also necessary to dry and cure the sprayed aluminum veneer to ensure its coating firmness and durability.

4、 Film sticking process

Film sticking is another important step in the manufacturing process of 2.5mm fluorocarbon aluminum veneer. Before applying the film, the polyester film needs to be cut and punched, and then pasted onto the surface of the fluorocarbon coating. During the film application process, attention should be paid to controlling the thickness and flatness of the film to ensure the overall aesthetics and waterproof performance of the aluminum veneer surface.

5、 Surface treatment

After completing the painting and film application, further treatment is required on the surface of the 2.5mm fluorocarbon aluminum veneer. Generally speaking, surface treatment such as anodizing can be used to enhance the wear resistance and corrosion resistance of aluminum veneer. Surface treatments such as polishing and drawing can also be carried out as needed to enhance the decorative and texture of aluminum veneer.

6、 Quality inspection and acceptance

After completing the manufacturing of 2.5mm fluorocarbon aluminum veneer, strict quality inspection and acceptance are required. Check whether the size, shape, coating quality, film quality, and surface treatment quality of the aluminum veneer meet the design requirements and national standards. If any problems are found, they need to be adjusted and repaired in a timely manner.

The manufacturing process of 2.5mm fluorocarbon aluminum veneer includes steps such as raw material preparation, cutting and processing, coating process, film sticking process, surface treatment, and quality inspection and acceptance. During the manufacturing process, it is necessary to pay attention to safety and quality issues, and follow relevant manufacturing specifications and standards. Only by strictly following the manufacturing process can the quality and aesthetics of 2.5mm fluorocarbon aluminum veneer be guaranteed.

Customer service QQ

Customer service QQ