Industry information

Company News

- Aluminum veneer customization, creating the art of personalized space

- Aluminum alloy air conditioning cover, the secret weapon to protect the coolness of summer

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum curtain wall: a shining pearl in modern architecture

- Customized aluminum veneer, making the building full of personality!

Industry dynamics

- Production process and technical analysis of carved curtain wall aluminum veneer

- Aluminum curtain wall, creating a new fashion in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Characteristics and advantages analysis of perforated baked paint aluminum veneer

- Aluminum alloy air conditioning cover: the guardian of summer coolness!

Frequently asked questions

- What are the unique advantages and characteristics of aluminum veneer?

- What are the common styles and characteristics of the application of aluminum veneer in the home decoration industry?

- What will be the future innovation and development trend of aluminum veneer?

- What is the current supply and demand situation in the aluminum veneer market?

- What are the unique design and application advantages of aluminum veneer curtain walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Processing technology and manufacturing process of 2mm aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 1, 2025 21:18:22

- Click:0

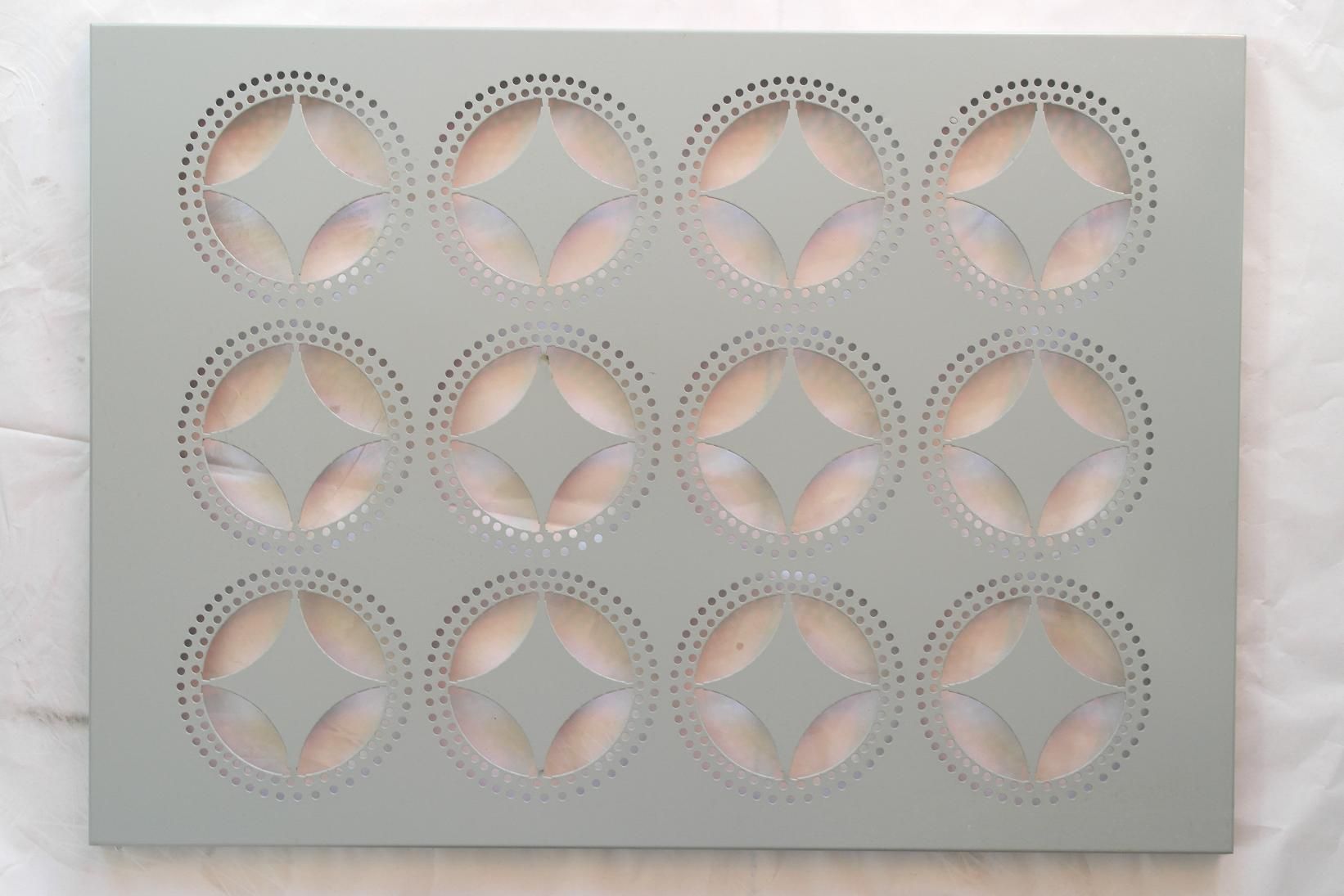

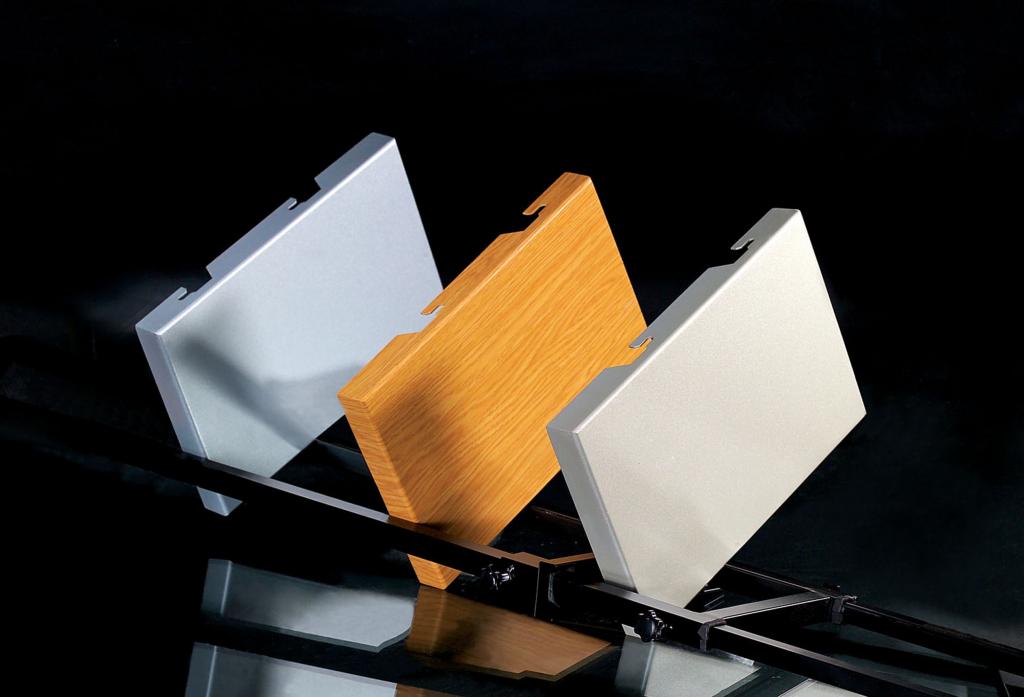

As a commonly used building decoration material, the processing technology and manufacturing process of 2mm aluminum veneer have a significant impact on its quality and performance. The following will provide a detailed introduction to the processing technology and manufacturing process of 2mm aluminum veneer from multiple aspects.

1、 Material preparation

Before processing and manufacturing 2mm aluminum veneer, it is necessary to prepare the required raw materials and equipment. It mainly includes the following aspects:

1. Aluminum: It is necessary to choose high-quality 2mm aluminum as the raw material to ensure its strength and corrosion resistance.

2. Cutting equipment: such as shearing machines, punching machines, laser cutting machines, etc., used to cut aluminum into the required size and shape.

3. Drilling equipment: such as electric drills, landing gear, etc., used for drilling or slotting on aluminum materials for subsequent processing.

4. Welding equipment: such as argon arc welding machine, gas shielded welding machine, etc., used for welding or connecting aluminum materials.

5. Surface treatment equipment: such as anodizing equipment, spraying equipment, rolling equipment, etc., used for surface treatment of aluminum materials.

2、 Processing steps

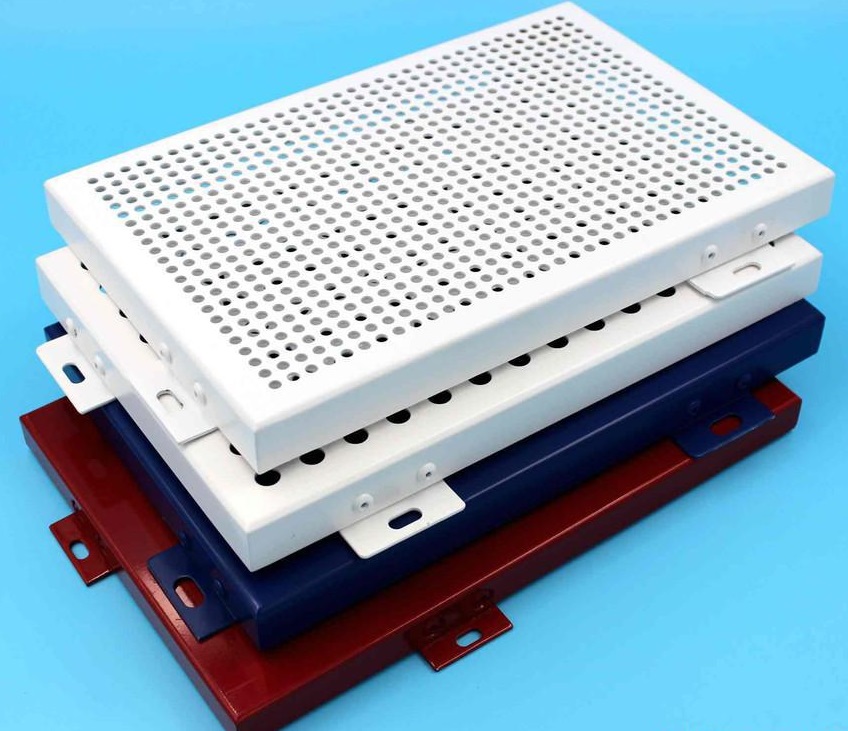

The processing steps of 2mm aluminum veneer mainly include the following aspects:

1. Cutting: According to the design requirements, use the corresponding cutting equipment to cut the aluminum material into the required size and shape.

2. Drilling/slotting: Use drilling equipment or slotting tools to drill or slotting on aluminum materials for subsequent processing.

3. Welding/Joining: Use welding equipment or joining tools to weld or join aluminum materials to form the desired structural framework.

4. Surface treatment: According to the needs, use corresponding surface treatment equipment to treat the aluminum surface, such as anodizing, spraying, rolling, etc.

3、 Production process

The production process of 2mm aluminum veneer mainly includes the following aspects:

1. Design plan: Based on the architectural design requirements and customer needs, develop a corresponding design plan, including the size, color, texture, etc. of the aluminum veneer.

2. Material preparation: Prepare the necessary raw materials and equipment according to the requirements of the design plan.

3. Processing and production: According to the design plan and processing steps, carry out the processing and production work of aluminum veneer.

4. Quality inspection: Conduct quality inspection on the 2mm aluminum veneer processed and manufactured to ensure that it meets the design requirements and national standards.

5. Packaging and transportation: Packaging and transportation of qualified 2mm aluminum veneer for sale and installation.

4、 Summary

The processing technology and manufacturing process of 2mm aluminum veneer are key links to ensure its quality and performance. In practical operation, it is necessary to strictly follow the design scheme and processing steps, and pay attention to quality inspection, packaging and transportation to ensure that 2mm aluminum veneer can meet the needs of building decoration.

- previous page:Decorative effect of 2.5mm aluminum veneer

- Next page:Decorative effect and aesthetics of 2mm aluminum veneer

Customer service QQ

Customer service QQ